So how can R&B Industrial help you to minimise explosive flammable, and hazardous workplace areas?

We have completed more than 400 DSEAR (Dangerous Substances and Explosive Atmospheres Regulations) Risk Assessments and Hazardous Area Classifications, aiming to improve the quality, depth and clarity of our advice every time. We strive to consider the latest codes, standards and guidance in our reports, to the extent that they apply in the UK, and consult a wide range of sources.

Our extremely knowledgeable technical department will help you identify and reduce any potential flammable or explosive atmospheres you may have, whilst using current HSE guidance. (DSEAR regulations 2002) https://www.hse.gov.uk/fireandexplosion/dsear-regulations.htm

Our reports generally focus on Regulations 5 (Risk assessment) and 7 (Hazardous Area Classification), which are considered adequate to fulfil the requirements of an explosion protection document under the DSEAR ACOP L138. https://www.hse.gov.uk/pubns/books/l138.htm However, unlike most consultancies we are able to practically assist clients in reducing risk / extents of zone (Regulation 6), and provide corrective engineered solutions. Our reports can also advise on correct identification of containers and pipes containing hazardous substances (Regulation 10) and comment on whether current emergency procedures and training (Regulations 8 and 9) are adequate.

In this way we can often save our customers £10,000s or even £100,000s by not having to unnecessarily over-zone and spend on ATEX equipment.

We are also able to provide explosion protection and mitigation solutions, such as explosion venting, back pressure flaps, pressure relief, divert systems and ATEX/UKEX electrical equipment.

How to Reduce Extents of Zone

One problem which our clients frequently face is over-classification of hazardous areas. This can make compliance extremely expensive, or in some cases impossible – if the equipment is simply not available as an ATEX version and further measures cannot control the risk. The principal codes and standards used (BS EN60079-10 parts 1&2, EI15, various LPG and gas codes, etc.) can be over-conservative in some situations and there is no statutory requirement to follow these rigidly. In many cases reducing extents of hazardous areas is possible as follows:

Pressurised gases and Liquids: The main issue with the standards is that they do not account for the turbulence of the release, which tends to ensure that a flammable gas is rapidly diluted to safe levels within a short distance, except in enclosed spaces. The HSL’s QUADVENT model can be used to make more realistic predictions and can eliminate or reduce zoned regions around pressurised gas transport or storage in many cases. The QUADVENT 2 software tool is also able to make predictions for pressurised liquid releases. Practical measures may also be taken, for example reducing the compressed air pressure of a spray gun or installing ventilated enclosures. Although R&B Industrial do not own a QUADVENT 2 license, we can carry out basic calculations under the original QUADVENT model.

Liquid pool releases (leaks and spills): The standards are often more realistic in this case as there may be little atmospheric turbulence and vapour concentrations can build up. Nevertheless, material safety data sheets do not always give accurate information regarding relevant substance properties. For example, the flash point and vapour pressures are often based on the properties of the worst-case component.

By estimating the true flash point of the mixture it can sometimes be shown that it is more than 10C higher than the highest anticipated temperature, which will generally allow the hazardous area to be removed, provided that there is no potential for mist formation. More accurate calculation of the mixture vapour pressure can also reduce extents of zone, especially if temperature is also controlled, as the release rate will be reduced. Use of bunding can also limit the release area and hence the release rate.

Dust Releases: there is very little guidance on the extents of dust zones in BS EN60079-10-2:2015, other than tentative notes suggesting that 1m and 3m are often sufficient for zones 21 and 22 respectively. In practice, a better knowledge of the process and the dust properties can often be used to justify much smaller extents of zone. For example, terminal velocities of the dust particles can be estimated and compared with air flow distributions, which can be assessed based on our expertise in LEV systems. In some cases, the amount of dust released may be used to justify a smaller extent of zone based on the minimum explosive concentration. If a dust or powder is sufficiently cohesive, it may be possible to justify removing the hazardous area altogether.

- In all cases, sufficient ventilation local or general will allow reducing of zone category (e.g. from zone 1/21 to zone 2/22). In some cases the area classification can be eliminated entirely For example: Release rates can be determined experimentally, and used to confirm dilution by a safe margin (e.g. below 25% or 10% of lower flammability limit), so that ducts can be considered non-hazardous

- enclosing the process and ensuring a sufficient negative pressure / or face velocity is maintained, to eliminate zoning outside the enclosure

- certify the ventilation is reliable & robust, extents of zones (hazardous areas) can be precisely controlled, reduced or eliminated.

Note: additional controls & protective measures may be required, such as spark / fire detection/suppression, interlocking process operations, safety instrumented or fault-tolerant systems, etc.

Non-Electrical Ignition Risk Assessment

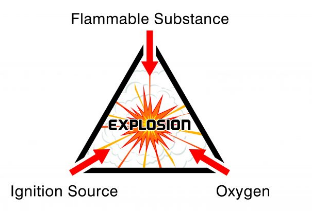

Non-electrical equipment can cause explosion by friction, impact, static, hot surfaces and many other methods – therefore all equipment designed to be used in Explosive Atmospheres should be risk assessed to ensure that such an explosion can not happen

Where a hazardous area classification cannot be reduced, either by a more detailed analysis or by changes to equipment or procedures, it is often possible to carry out a Non-Electrical Ignition Risk Assessment (NEIRA). This can allow use of non-ATEX equipment in hazardous areas after minor modifications for example:

- replacing non-ATEX electrical components;

- installing current limiting barriers on sensors;

- installing thermocouples to detect emerging hot spots; or

- selective use of non-sparking components.

We have carried out NEIRAs on equipment which has not been formally ATEX marked, and made the modifications necessary for it to be safe in a hazardous area; references can be provided.

For more information about our detailed DSEAR risks assessments go to our main DSEAR Risk Assessments page.

Please do not hesitate to give us a call today and talk to one of our technical specialists on 01264 351844.