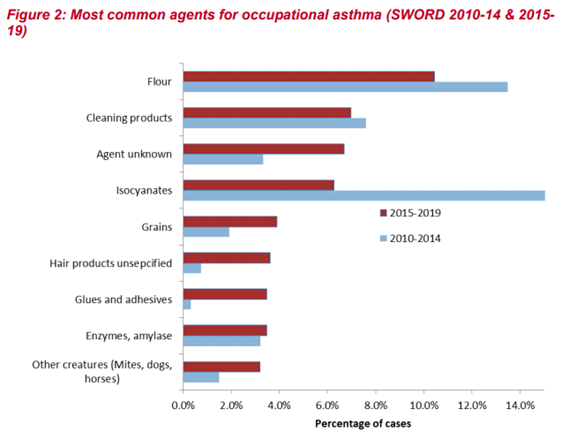

Flour dust is the leading cause of occupational asthma in the UK. Workers in bakeries and flour mills are 80 times more likely to develop asthma than the general population. At least 10% of bakers probably suffer from occupational asthma.

It has been known since Roman times that exposure to flour dust can cause lung disease. We now know that natural enzymes in the flour are the cause. So are your workers at risk of inhaling flour dust? The answer is probably yes if:

- clouds of flour dust particles are visible in a shaft of light

- flour deposits are visible on surfaces above 2m

Adequate dust controls include local exhaust ventilation around weighing stations and dough making machines. General ventilation systems aren’t usually sufficient to control dust and prevent baker’s asthma.

Any dust will cause bouts of coughing if inhaled in excess, but the symptoms of respiratory issues caused by flour can go unnoticed for several years. A running or blocked nose, itchy eyes and wheezing can indicate the onset of asthma. If the symptoms are worse during the working week and ease off at weekends, the asthma is probably related to air quality at work. Once asthma has fully developed, the best (often only) treatment is to change occupation to avoid exposure totally.

Many bakeries expect their workers to wear a disposable particle mask, but these are uncomfortable and unlikely to satisfy HSE requirements. Under COSHH guidance, provision of respiratory protection equipment (RPE) should only be considered as a last resort. Disposable masks must be face-fit tested and may only be used for brief tasks <1hr. Employers should follow a ‘hierarchy of control’, where engineering controls must take priority over simply relying on RPE.

Further, compliance with dust exposure limits is not enough. Since flour dust is formally classified as a respiratory sensitiser, employers are legally obliged to:

- Reduce worker exposure to ‘as low as reasonably practical’ (ALARP)

- Implement health surveillance checks on their exposed workers (normally annually). These must be done by an occupational health professional familiar with the signs of occupational asthma.

- Check the concentration of airborne dust in the workplace. This should be done by a competent occupational hygienist as a report that lacks sufficient detail won’t satisfy the HSE. Best practice is to monitor every 1-3 years, depending on the outcome of health surveillance and previous monitoring.

- Specify and enforce safe working practises. These could include careful tipping of flour bags, safe disposal of empty bags, cleaning procedures, enclosed or locally ventilated areas for weighing, sifting and mixing and use of RPE as a last resort where LEV is not practical.

At R & B Industrial we can carry out individual assessments, producing reports that comply with HSE and BOHS requirements. These reports contain practical and cost-effective solutions to solve air quality issues. If LEV is required, we can quote to manufacture and install what is necessary. We also offer Face Fit Testing to ensure that RPE is protecting individuals as it should be. All extraction systems must be properly maintained and undergo comprehensive inspection at least every 14 months. To meet this requirement, R&B Industrial offers LEV servicing and testing by our qualified P601 engineers.

On top of employers’ moral duty to protect their workers, poor control and monitoring of flour dust exposure can be very expensive. Over and above any HSE fine, compensation claims, recruitment of new staff and reputational damage can easily cost £100,000s for severe cases where the worker must change occupation.

If this article has raised any questions regarding flour dust in your workplace and you are interested in any of our services, please get in touch.